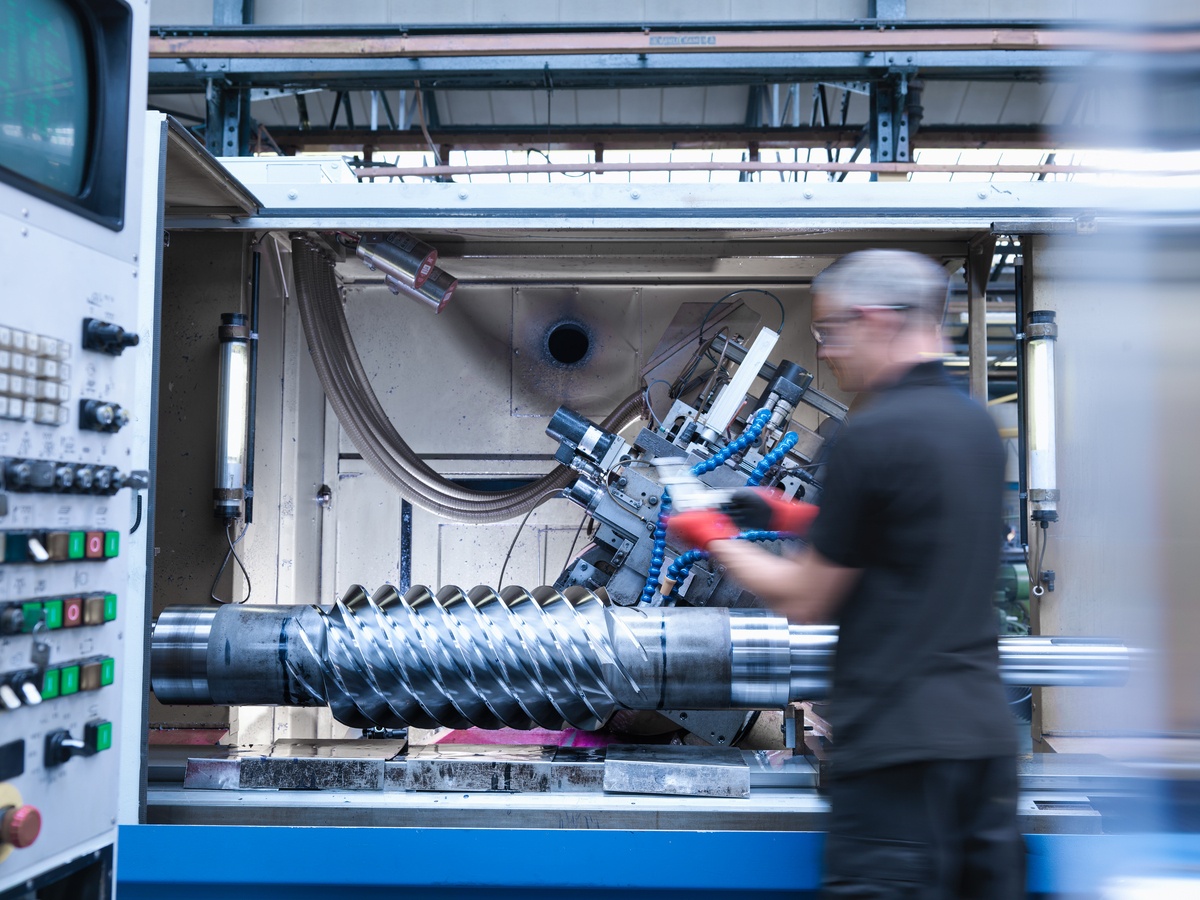

The most discussed topic among specialists concerns the interconnection and integration of technologies within the scope of Industry 4.0 and 5.0. But what are the distinctive tools of these two evolutionary phases? HTM SRL is at the forefront in adopting and developing solutions based on these technologies to offer increasingly high-performance and efficient precision molds.

Industry 4.0: Automation and Intelligent Connection

Industry 4.0 has revolutionized the manufacturing sector by introducing automation and real-time system connectivity. Key technologies such as the Internet of Things (IoT) allow real-time monitoring of production processes, improving quality optimization and reducing waste.

The most important tools of Industry 4.0 include:

- • Big Data and Predictive Analytics: They allow companies to make more informed decisions and implement predictive maintenance strategies, reducing downtime and operational costs.

- • Advanced Robotics and Cobots: Collaborative robots improve productivity and operator safety, reducing the margin of error.

- • Artificial Intelligence (AI) and Machine Learning: They optimize production processes and improve mold quality.

- • Digital Integration and Cloud Computing: They enable centralized data management and interconnection between devices and machinery.

Industry 5.0: Customization and Sustainability

While Industry 4.0 focused on automation, Industry 5.0 focuses on customization and the centrality of humans in the production process. Key tools of Industry 5.0:

- • 3D Printing and Additive Manufacturing

- • Augmented Reality (AR) and Virtual Reality (VR): They improve design and operator training, optimizing human-machine interaction.

- • Blockchain for the Supply Chain: It ensures transparency and traceability, improving the security of production processes.

- • Sustainability and Reduction of Environmental Impact: Advanced technologies allow reducing energy consumption and the use of non-recyclable materials, aligning with sustainable development goals.

HTM: Innovation and Cutting-edge in Industry 4.0 and 5.0

Industry 4.0 and 5.0 technologies can be successfully applied in the mold production sector. Our company has adopted digital and automated solutions to improve mold precision and optimize production processes.

The Benefits of Industry 4.0 and 5.0

- • Efficiency and Cost Reduction: Thanks to real-time data analysis, we can predict anomalies and optimize energy consumption.

- • Superior Quality: The use of artificial intelligence and IoT ensures a high standard in mold production.

- • Greater Customization: 3D printing and advanced design technologies allow us to offer tailor-made solutions for each customer.

- • Environmental Sustainability: The adoption of eco-friendly practices and resource optimization are integral parts of our commitment to a more sustainable industry.

Conclusion

Industry 4.0 and 5.0 represent the future of industrial production and HTM SRL is at the forefront in adopting these technologies. Thanks to the integration of advanced automation, HTM guarantees molds of the highest quality, reduced production times, and greater production efficiency.

Investing in new technologies is the key to success in an increasingly competitive market. Trust HTM SRL to enter the era of intelligent manufacturing!