In the world of industrial manufacturing, plastic injection molds are a fundamental technology for producing components with high precision and repeatability. HTM SRL, with over 30 years of experience, excels in the design and manufacture of cutting-edge molds, providing innovative and customized solutions for various industrial sectors.

What Are Plastic Injection Molds?

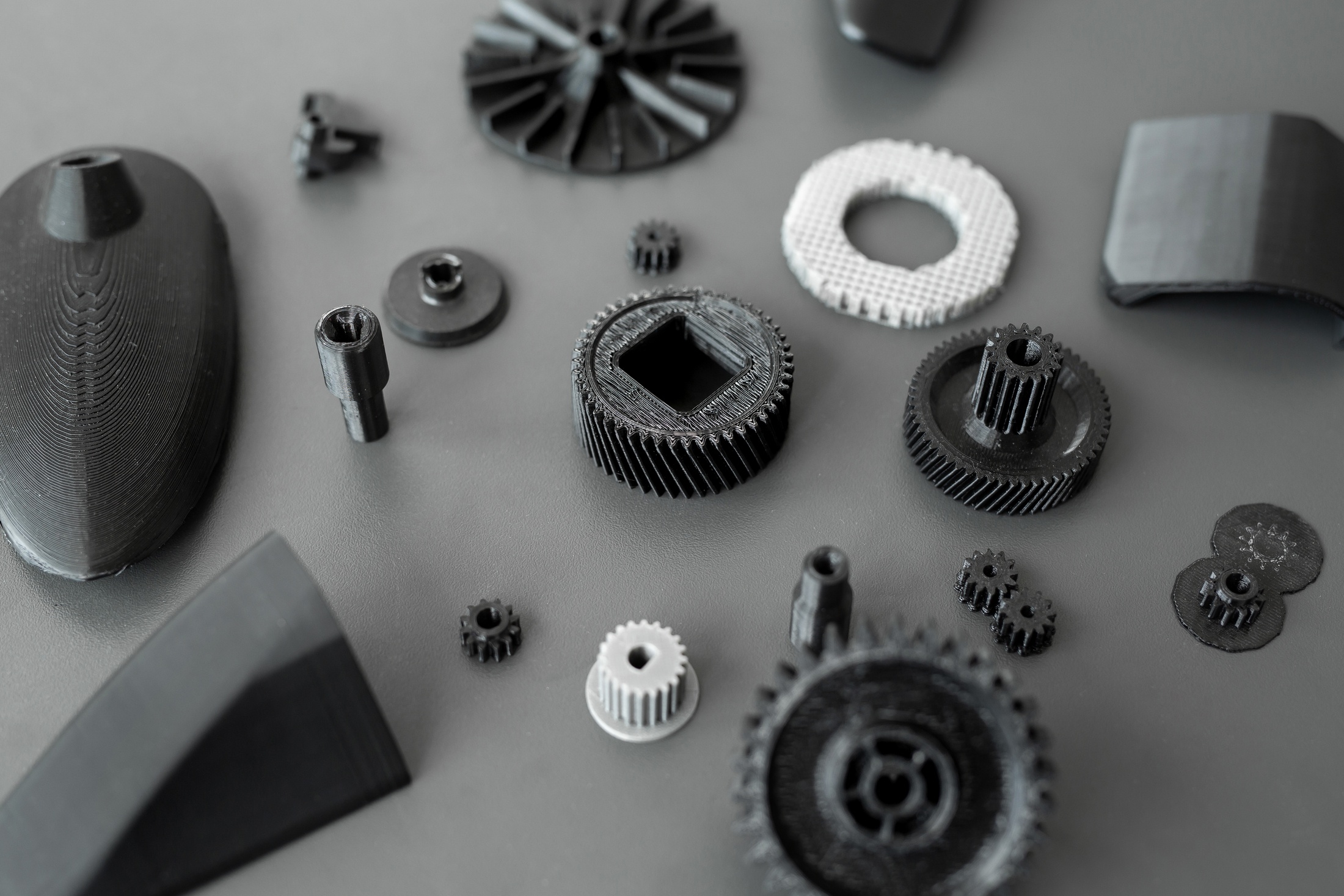

Plastic injection molding is a process in which molten thermoplastic material is injected at high pressure into a closed mold. Once cooled and solidified, the part is ejected, ready for use. This method is used to produce high-quality components with complex geometries and precise details.

Injection molds are essential tools in this process and must ensure:

- • Maximum dimensional precision for uniform and repeatable parts.

- • High strength and durability, thanks to the use of advanced materials.

- • Optimization of material flow to reduce defects and waste.

- • Integration of efficient cooling systems to reduce cycle times.

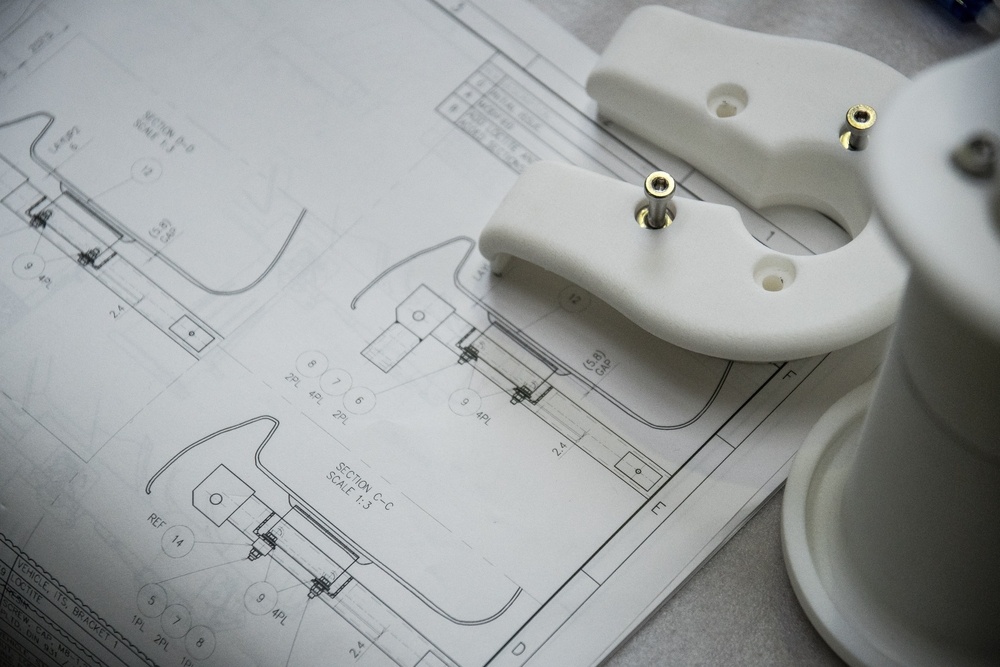

HTM’s Innovation in Injection Mold Design

HTM SRL designs and manufactures plastic injection molds using advanced technologies, such as:

- • Moldflow Analysis: Advanced simulations to optimize material distribution and prevent molding defects.

- • Co-design with customers: A collaborative approach to develop tailored solutions that improve performance and production efficiency.

- • High-quality materials: Use of resistant steels to ensure greater mold longevity.

- • CNC precision and Industry 4.0: Machining with high-precision and digital control machinery for uncompromising quality.

Advantages of HTM’s Plastic Injection Molds

Relying on HTM SRL means getting molds with:

- • Superior quality and precision, reducing defects and waste.

- • Optimized production costs, thanks to improved production cycle efficiency.

- • Total customization, adapting to the specific needs of each customer.

- • Post-sales support and maintenance, to ensure long operational life of the molds.

Applications and Sectors of Use

HTM’s plastic injection molds are used in various sectors:

- • Automotive: Structural components, dashboards, internal and external parts.

- • Electronics and Mechatronics: Housings and technical components for electronic devices.

- • Food Industry: Containers, utensils, and food packaging.

- • Medical: Precision devices and healthcare items.

- • Luxury and Consumer Goods: Customized items with high-quality finishes.

HTM: The Ideal Partner for Plastic Injection Mold Production

With a consolidated experience and a constant focus on innovation, HTM SRL is the ideal choice for companies looking for reliable, efficient, and customized molds. Thanks to the integration of the most modern technologies and a team of highly qualified experts, HTM guarantees high-quality solutions that meet the challenges of industrial production.

If you want to optimize your injection molding process and obtain superior quality molds, HTM SRL is the partner for you. Contact us for a consultation and discover how we can take your production to the next level.