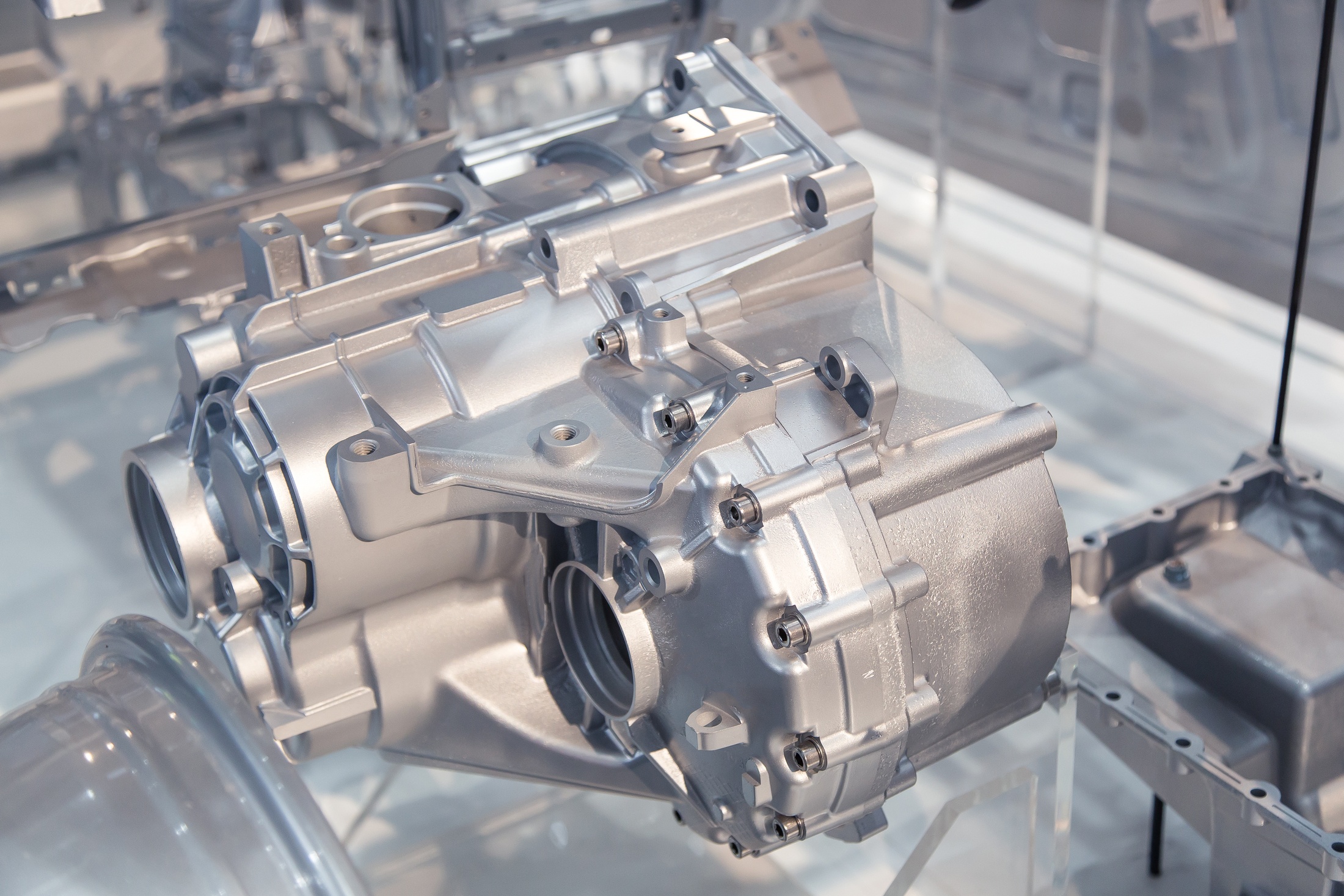

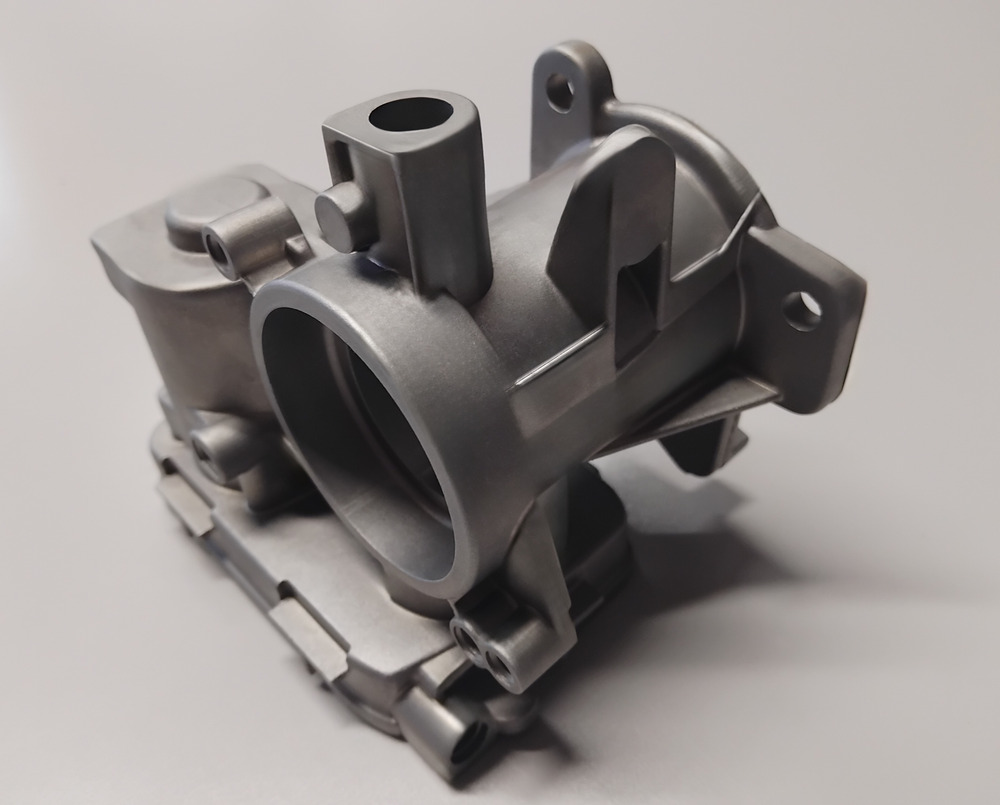

High Pressure Die Casting (HPDC) is one of the most widely used processes in the manufacturing industry for producing lightweight, strong, and complex-shaped metal components. This technology allows for the production of finished parts in rapid times and with very high precision tolerances. Aluminum HPDC molds are one of the key elements for the success of this technology, as they are designed to ensure high quality and productivity in every production cycle.

What is High Pressure Die Casting (HPDC)?

High-pressure die casting is a process that involves injecting molten metal, typically aluminum, into a metal mold at very high pressure (up to 1000 bar). The molten metal quickly fills the mold cavities and solidifies in short times, allowing for the production of components in series with precision and speed. This process is particularly suitable for the production of complex parts, with high-quality finishes and without the need for additional post-production operations.

Features of Aluminum HPDC Molds

High-pressure die casting molds are designed to withstand the high temperatures and pressures they are subjected to during the process. Their design and construction require advanced skills, as they must meet durability, precision, and speed requirements. HTM – High Technology Mould stands out in the production of HPDC molds thanks to the use of innovative technologies and high-quality materials.

The main features of HTM SRL’s aluminum HPDC molds include:

- • High-Strength Material: HTM uses alloy steels and special wear- and heat-resistant materials to ensure maximum mold durability.

- • Optimized Design: Thanks to Moldflow analysis and co-design with customers, HTM molds offer a uniform flow of molten metal, reducing defects and improving final quality.

- • High Precision: With the use of state-of-the-art CNC machinery, HTM guarantees molds with extremely precise dimensional tolerances.

- • Advanced Cooling Systems: HTM integrates optimized cooling channels to speed up the cycle time and ensure controlled temperature during the process.

Advantages of HTM’s Aluminum High Pressure Die Casting (HPDC) Molds

Relying on HTM – High Technology Mould for the production of HPDC molds offers numerous advantages:

- • Rapid and Optimized Production: Our molds are designed to ensure efficiency and reduce production times.

- • High Quality and Precision: Thanks to experience and advanced technologies, HTM ensures components with excellent finishes and tight tolerances.

- • Customization and Flexibility: Each mold is tailor-made to meet customer needs, ensuring optimal solutions for any sector.

- • Technical Support and Maintenance: We offer after-sales support and maintenance services to maximize the life and performance of the molds.

Application Sectors of Aluminum High Pressure Die Casting (HPDC) Molds

HTM SRL’s high-pressure die casting molds find application in various sectors:

- • Automotive Industry: Production of structural components, engines, chassis, and cooling systems.

- • Aerospace Sector: Creation of lightweight and strong parts for aeronautical structures.

- • Electronics Sector: Manufacturing of enclosures and high-precision components for electronic devices.

- • Appliances: Production of robust and lightweight parts for refrigerators, washing machines, and other appliances.

HTM – Excellence in Aluminum HPDC Molds

High-pressure die casting molds are essential tools for modern industrial production. HPDC technology allows for the production of lightweight, strong, and complex-shaped components while maintaining high standards of precision and production speed.

With thirty years of experience and the use of cutting-edge technologies, HTM – High Technology Mould is the ideal partner for the production of HPDC molds. We offer tailor-made solutions, certified quality, and specialized technical support to ensure the maximum performance of your production.

Rely on HTM SRL to obtain excellent molds designed to maximize your company’s efficiency and reduce operating costs.